Automotive suppliers are often selected based on an RFQ, a price point, and assurances of reliable deliveries. All of these are critical to choosing the right supplier, but focusing narrowly on these factors opens your supplier selection method up to a few major pitfalls.

It’s not enough to know what to look for in an automotive supplier—you’ve also got to know what not to do in your search. Avoid potentially costly mistakes like these:

Searching For a “Hands-Off” Relationship

It might seem like an advantage, in theory. Out of sight, out of mind. A self-sufficient supplier should be able to do their job while you do yours, no questions asked. Right?

The truth is that a collaborative relationship with a proactive supplier is more budget-friendly. Frequent touch points will result in fewer miscommunications, clearer expectations, and more opportunities to find cost-downs. Look for a supplier that prioritizes relationship-building and cooperation on areas of mutual self-interest.

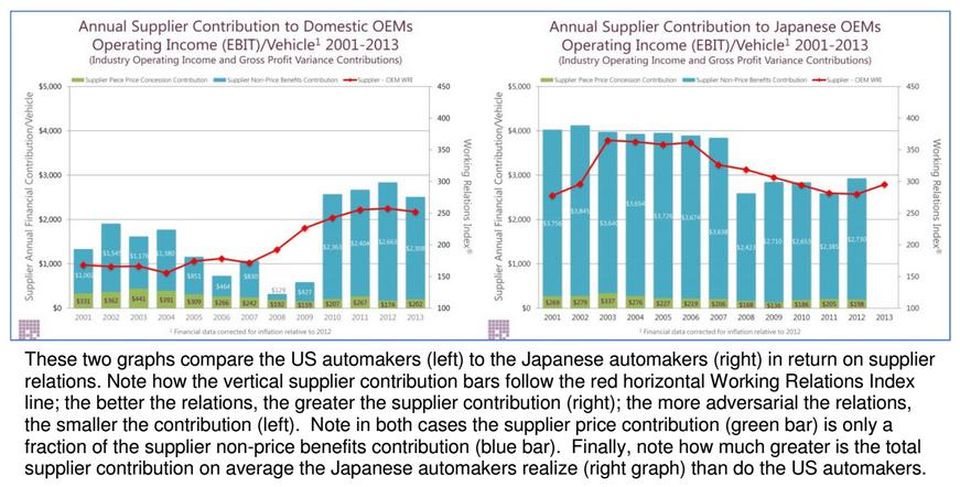

The insights in the 15th annual “North American Automotive - Tier 1 Supplier Working Relations Index Study” back up the advantages of a strong supplier relationship. Ford, General Motors, FCA US (Chrysler), and Nissan collectively would have earned $2 billion more in operating profits in 2017 had their supplier relations improved as much as Toyota’s and Honda’s did during the year.

Liking What You Hear, But Never Looking For Yourself

A supplier might look incredible on paper, or talk a big talk, but we live in a 3D world. The RFP/RFQ process can be a little impersonal—it’s important to supplement the paper portion of your supplier selection method with real-world insights.

Consider visiting the factory floor, conducting a live audit of their manufacturing process, or testing product samples. These will save you from investing too much time on a supplier who says everything you wanted to hear, but can’t pass the eye test.

Focusing on Product, But Not on Service

It’s natural to assume product concerns should dominate any sound automotive supplier selection method. However, a narrow focus on product quality, price, and availability will leave out one of the most critical elements of any business relationship: customer service. Even fantastic, cost-efficient automotive adhesives are hamstrung when the supplier doesn’t provide top-notch service around them.

According to Forbes, “the economic value of the suppliers’ non-price benefits can greatly exceed the economic benefit realized from suppliers’ price concessions.” As you can see in the chart below, a supplier’s non-price benefits average about 4-5 times the impact of price concessions, and sometimes much more (price is in green, non-price is in blue).

A great product matters, of course. But look carefully at a supplier’s reputation and their standard procedures for handling customer service before you sign on the dotted line.

Saving on Price, Only to Lose on Cost of Distance

There are hidden costs to switching from a local supplier to one that’s significantly further away. Even if a supplier nails your price point needs, think about the impact of their location on shipping and delivery costs, as well as the other inconveniences of a long-distance partner:

- In-person meetings are tougher to arrange

- Their staff could be operating in a different time zone

- They may lack first-hand understanding of your region

- Deliveries could take longer and be less agile

None of these pitfalls are enough on their own to dominate your supplier selection method, but they all deserve attention. The long-term success or failure of the supplier relationship could hang in the balance.